Data Collection

During the initial phase of the project, my team and I spent two weeks collecting valuable information from various stakeholders such as Heineken, Tomra, Statiegeld Nederland, and Afvalvonds Verpakkingen. This involved having frequent meetings with them to understand the possibilities for product development. We also conducted extensive research through various methods such as conducting polls, observing, and reading research papers. All of this information was crucial in informing our approach towards the development phase of the project.

First Design Steps

After conducting extensive research, I discovered that while many people were willing to recycle their cans, the inconvenience of carrying them around made it a challenge. To address this issue, I decided to design a container that could be placed underneath outdoor bins for easy disposal.

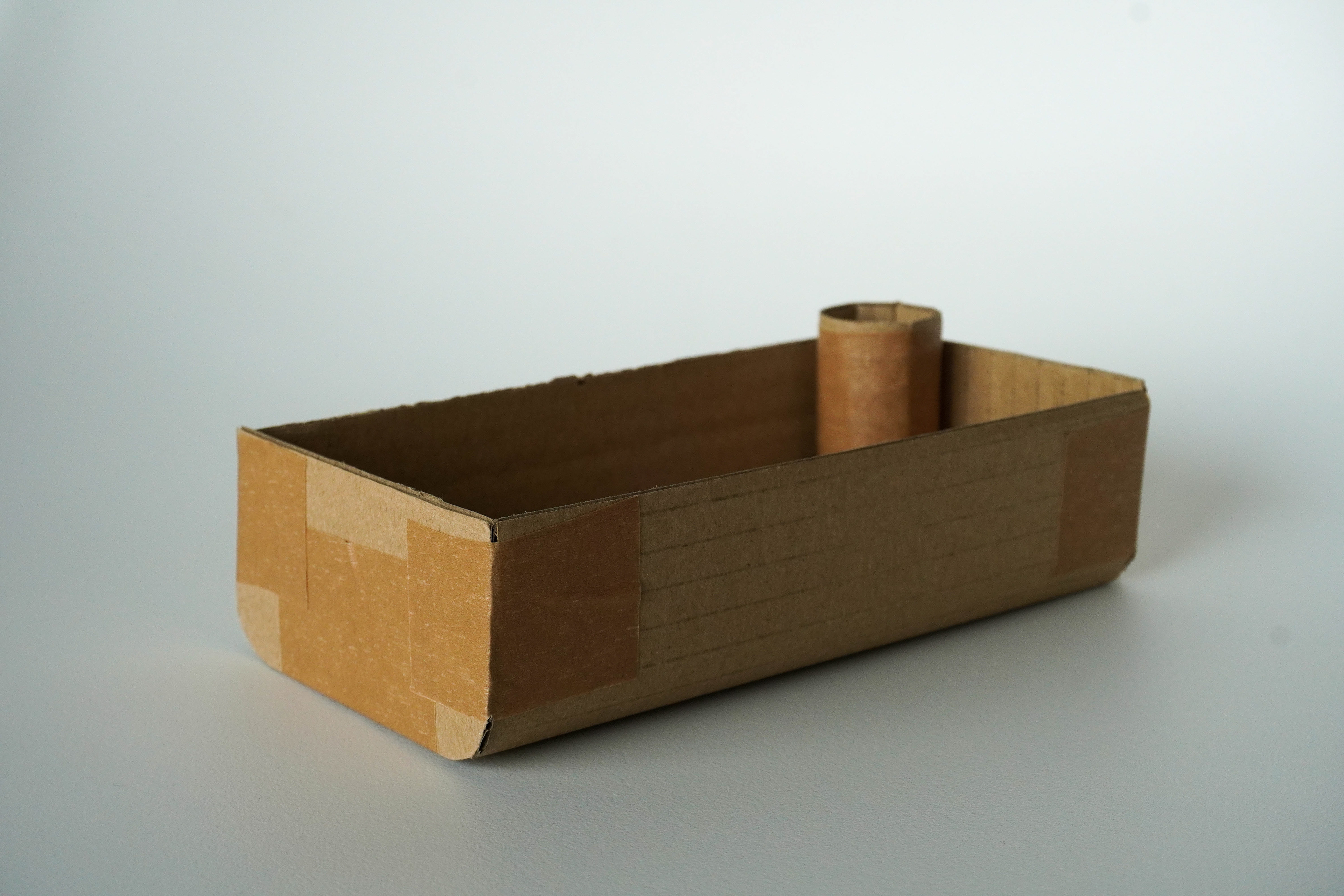

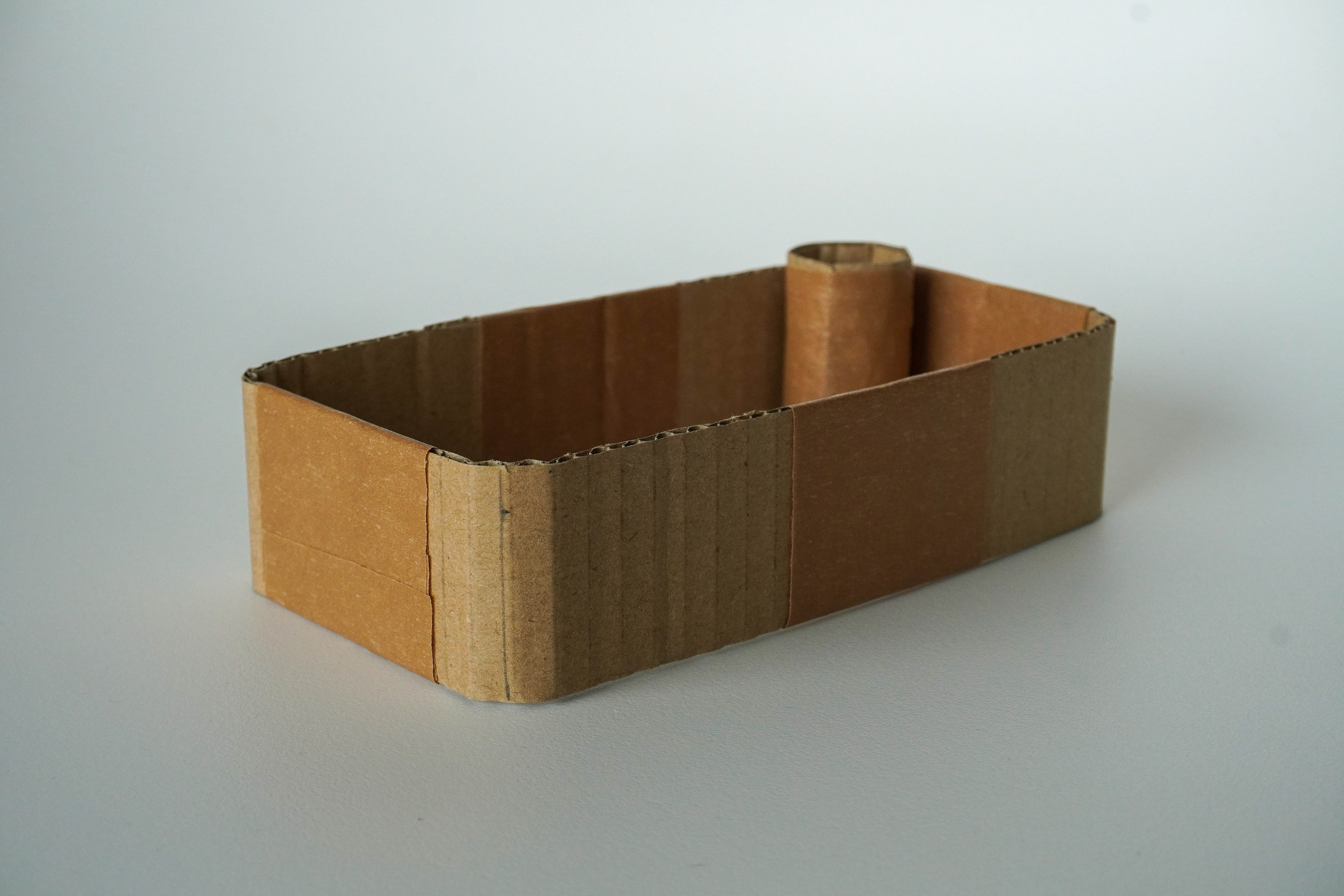

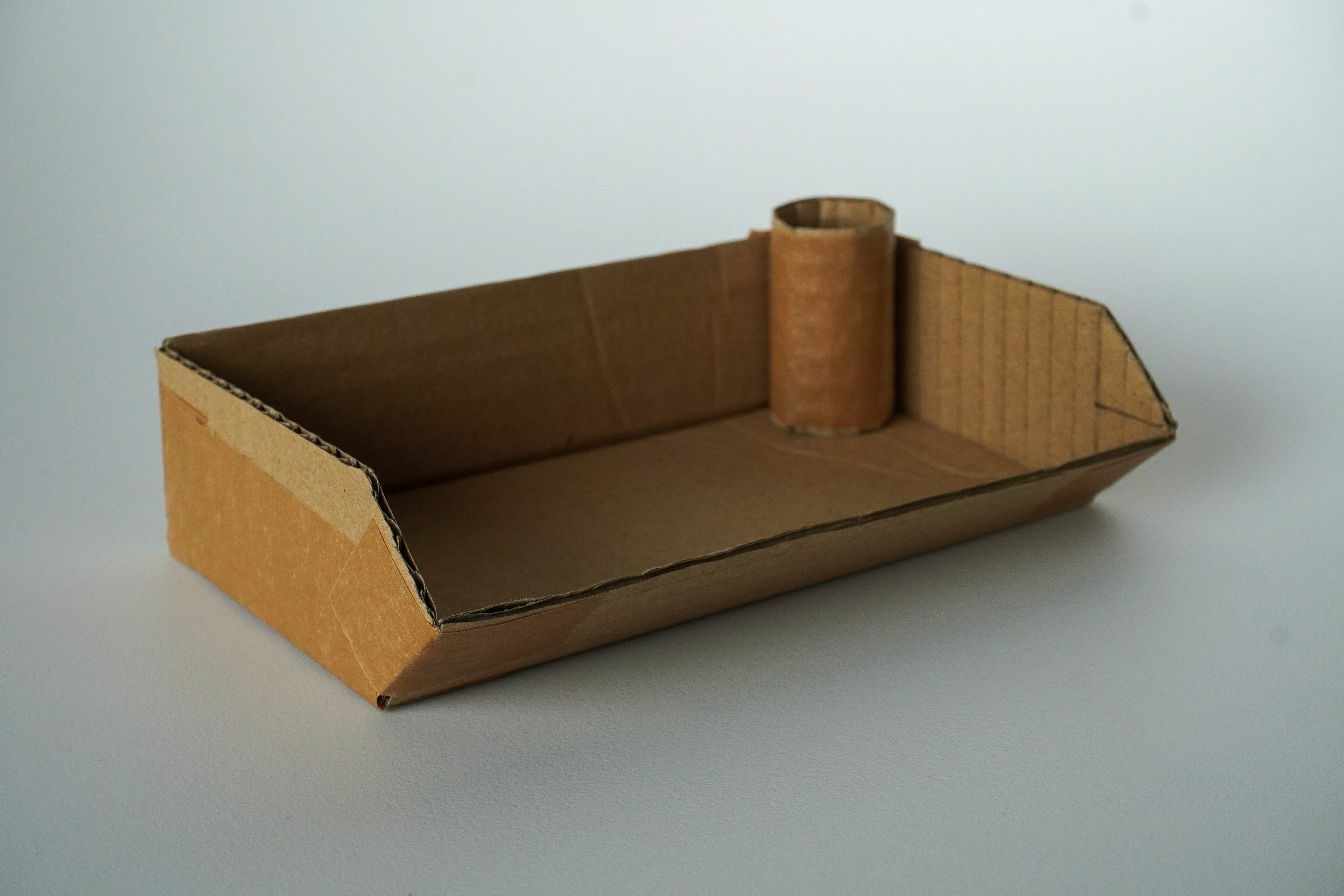

I began the design process by brainstorming and sketching out several ideas, considering factors such as mounting options, shape, material, branding, and more. Once I had a rough idea of what I wanted to create, I moved on to creating the first cardboard models. These initial prototypes allowed me to test out different designs and make adjustments before moving on to more advanced stages of the design process. Take a look at some of these early models below to see the evolution of my design.

Cardboard Model 1

Cardboard Model 2

Cardboard Model 3

Cardboard Model 4

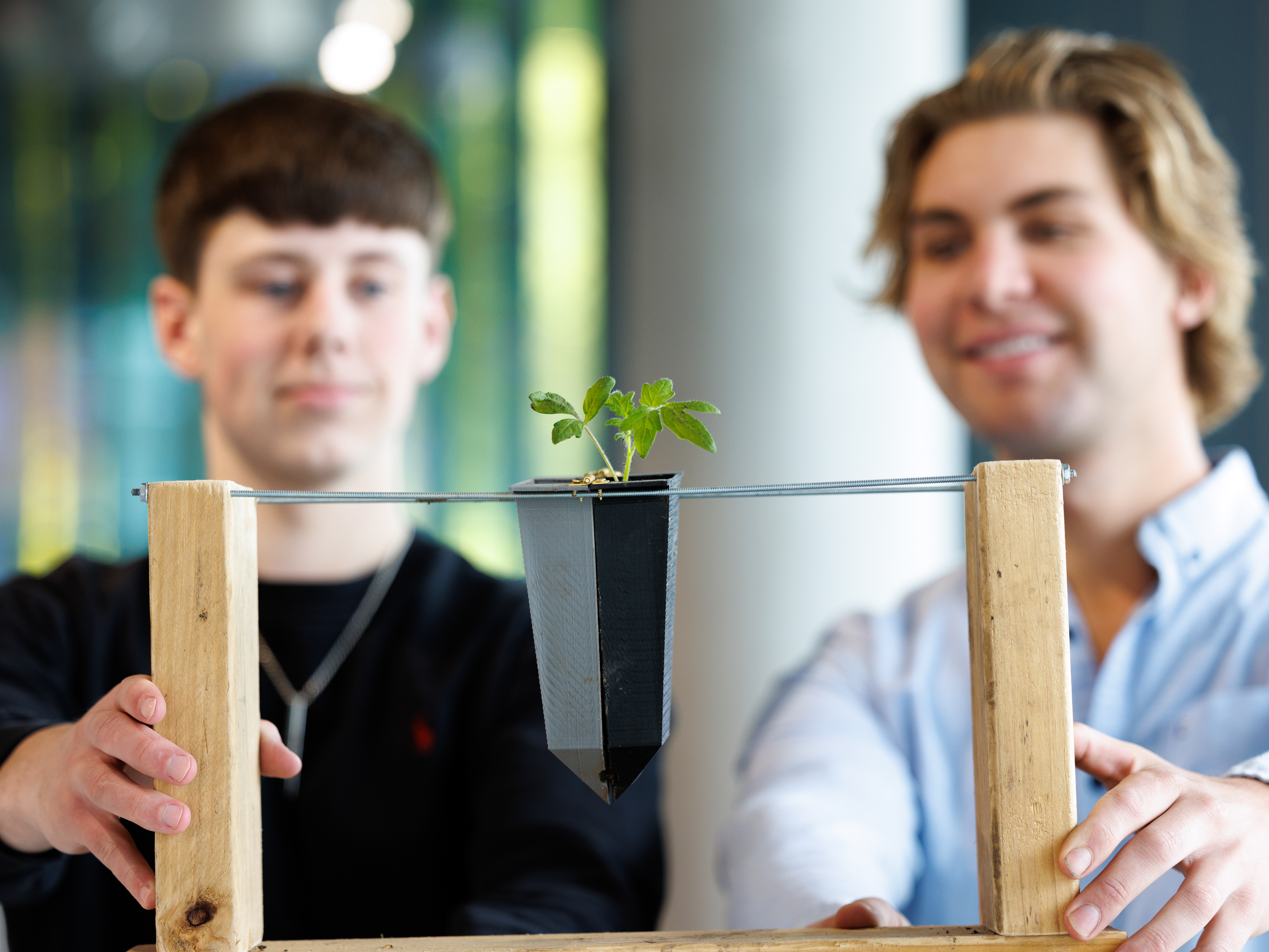

Prototyping

With the final design in mind, I began creating a 3D model of the product in Solidworks. One of the essential requirements for the project was that the container should be made from a single sheet of metal. I carefully crafted the design in Solidworks, ensuring that it could be cut from a single sheet of metal. In the image below, you can see the flat sheet metal design.

Once the basic design was complete, I moved on to adding the finer details, such as the mounting holes, Heineken branding, and drainage holes. To ensure that the container could withstand wear and tear, I tested it using Solidworks simulations that applied weight to the front of the container to mimic someone kicking it. Through these simulations, I was confident that the design was robust and could handle the daily wear and tear of regular use.